Stainless Steel Finishing Options

Several stainless steel finishing options alter more than just the appearance of the material. Whatever the intended use, choosing the right finish option is essential.

In projects when the design is a primary consideration, an attractive finish will enhance the appeal of the end-product. For example, in architecture and the automotive industries, different finishes can be used to achieve a variety of visual effects. In retail products, particularly kitchen appliances, stainless steel No. 4 finish is one of the most popular finishes available.

The choice of surface finish is also important where fabrication processes will be applied. Rough surface finishes are appropriate when the steel will be ground before painting and gluing. Smooth surface finishes are better where the steel will be blended.

The choice of finish should always be clearly specified and properly defined by standard industry designations.

The development of the surface finish standard

During the late 1970s, British Steel scientists found that dull polished finishes on stainless steel showed a wide range of surface roughness. Further testing revealed that steel with high surface roughness was heavily damaged by the polishing operations, whereas steel with low surface roughness was relatively unscathed.

During the mid-1980s dull polished finishes became widely used on projects such as high-profile architectural projects. However, it was soon discovered that some of these dull polished finishes had poor corrosion resistance, especially when exposed to seawater. Consequently, a new surface finish description was introduced which remains in use to this day.

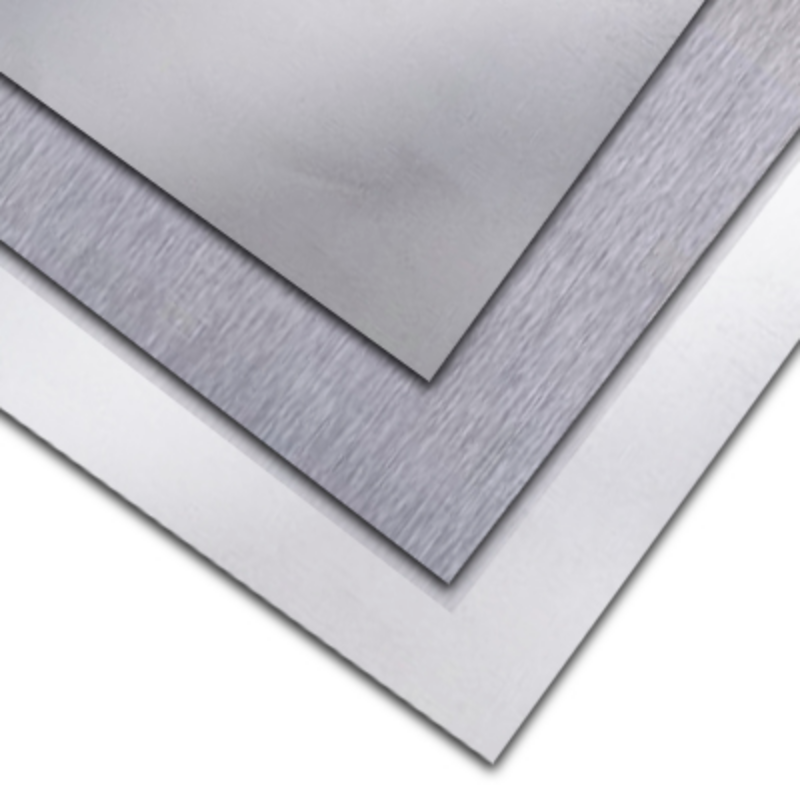

Three more common stainless steel finishing options are:

- No. 2B – Matte finish

- No. 4 – Brushed finish

- No.8 – Mirror finish

No. 2B – Matte finish

No. 2B is the mill finish, meaning it has not been processed further. Matte finishes are dull in appearance and are not ideal for aesthetic end uses. However, they’re a good choice where appearance is not important or when further finishing is intended. No. 2B Matte finishes are the least expensive of the stainless steel finishing options.

The finish is produced by ‘cold rolling’ stainless steel through special rolls or dies. The cold rolling produces a smoother, less pitted surface. Next, it is softened and de-scaled in an acid solution. The steel is given a final pass on polished rolls to further enhance its smoothness.

Common applications include:

- Chemical plant equipment

- Pharmaceutical equipment

- Papermill equipment

- Laundry and dry cleaning

- Refrigeration

- Sewage equipment

No. 4 – Brushed finish

The No. 4 Brushed finish can vary with different suppliers and even from batch to batch from the same supplier. The variations arise from differing manufacturing conditions, such as wearing the abrasive belts used in these finishes. Some level of variation should be expected when ordering No. 4 Brushed finish. It can be helpful to request a sample of a few square inches to ensure the finish achieves the desired effect.

Brushing the stainless steel produces a distinctive look with a muted luster and a pattern of fine parallel lines. It has strong decorative appeal without being too reflective, as too much reflectiveness can be undesirable. For example, overly reflective stainless steel accents on a building could be blinding in bright sunlight. The drawbacks to this finish include reduced corrosion resistance because the grooves of the finish are susceptible to rust.

The finish is created by sanding the stainless steel in one direction with a 120-180 grit belt, followed by softening with an 80-120 grit medium non-woven belt.

Gateway Arch

Common applications include:

- Jewelry and watches

- Home appliances

- Air conditioners

- Water heaters

- Architecture

- Automotive design

The Gateway Arch in St Louis, Missouri is the world’s tallest arch and is clad in brushed stainless steel.

The DeLorean DMC-12 sports car, most famous for being featured in the Back to the Future films, is paneled in brushed stainless steel.

No.8 – Mirror finish

Mirror finishes are highly reflective and created by polishing the stainless steel. The polishing process enhances appearance and consistency, making cleaning easier. It also masks the after-effects of welding and hides surface damage.

No. 8 Mirror finish is created by mechanically treating the surface with a series of progressively finer abrasives. Alternatively, a special rolling procedure is used which can simulate the appearance of mechanical abrasion. It is essential to remove deep scratches as any surface defects will be very noticeable on the finished product for this stage. The final process involves buffing the surface for 5-10 minutes to create a mirror-like, highly reflective finish.

A benefit of No. 8 Mirror finishing is that it improves corrosion resistance. The polishing eradicates crevices where corrosive particles can lodge themselves.

Common applications include:

- Mirrors

- Ornamental trim

- Clean rooms

- Column covers

- Wall panels

- Reflectors